The crucial importance of grounding braids in electrical installation regulations

Grounding Braids: Safety and Standards Electrical installations, also known as grounding braids, play an essential role in electrical grounding and protection systems. They ensure the safety of installations by minimizing the risk of electric shock and electromagnetic interference. This article explores the importance of grounding braidsand provides practical advice on their selection, installation and maintenance.

The basics of mass braiding

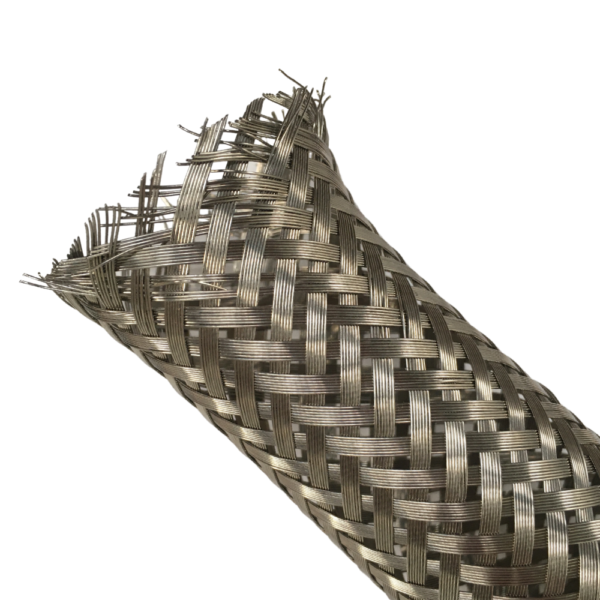

The ground braids are braided conductors made of tinned copper, aluminum, stainless steel and red copper. They are used to establish a reliable electrical connection between different parts of an installation, ensuring effective grounding. Their main function is to dissipate unwanted currents, protecting equipment and people from electric shock.

First of all, mass braiding has many advantages:

-

- Protection against electric shock: grounding braids provide safe grounding, reducing the risk of electric shock.

-

- Minimizing electromagnetic interference: Grounding braids help reduce interference, ensuring optimum performance of electronic equipment.

-

- Flexibility and durability: Their braided structure offers great flexibility and mechanical strength, suitable for a variety of applications.

Applicable regulations and standards

International Standards

Grounding braids are governed by international standards established by the International Electrotechnical Commission (IEC). These standards define technical specifications and performance requirements to ensure the safety and efficiency of electrical installations.

Mass braiding regulations in France

Secondly, in France, electrical installations must comply with NF standards, in particular NF C 15-100 for low-voltage installations. This standard specifies requirements for the design, implementation and testing of grounding systems, including the appropriate use of grounding braids.

Railway rolling stock - Connection of conductor braiding and shielded electrical cables must comply with standard NF F61-014.

Ground Braid Selection and Design Criteria : Safety and Electrical Installation Standards

Materials selection

Subsequently, the choice of material for ground braids depends on the application and the environment. Tinned copper is often preferred for its high conductivity and resistance to corrosion.Stainless steel is preferred for corrosive and abrasive environments(stainless steel ground braid). Our aluminum braids are often used in the automotive, aviation and transportation industries(automotive braided sleeving).

Dimensioning ground braids: Safety and electrical installation standards

Visit sizing of mass braids is crucial to their effectiveness. Length, width and thickness must be considered in relation to regulatory requirements and the specific features of the installation. Correct sizing guarantees effective dissipation of unwanted currents.

Installation and maintenance of ground braids

Good Installation Practices

In addition, for proper installation of ground braids, it is essential to follow certain key steps:

Ensure secure connections: Use appropriate connectors to securely fasten braids .

Check electrical continuity: Ensure that the grounding braid provides a continuous, reliable electrical connection.

Protect against mechanical damage: Install braids in such a way as to minimize the risk of mechanical damage.

Maintenance and checking of ground braids

Regular maintenance is essential to ensure the continued performance of ground braids. This includes periodic inspections to check the integrity of connections and the absence of corrosion or damage. Electrical continuity tests should also be carried out to ensure that grounding remains effective.

Case studies and application examples

Mass braiding case studies

Several case studies illustrate the importance of ground braids. For example, at an industrial facility, a properly installed ground braid prevented major electrical incidents, ensuring regulatory compliance and worker safety.

Grounding braids are essential for the safety and compliance of electrical installations. We know that a thorough understanding of regulations and good selection, installation and maintenance practices is crucial for professionals in the industry. By following current standards and keeping abreast of best practices, you can ensure safe and efficient electrical installations.