Flat electrical grounding braids: An essential element for electrical conductivity and grounding

In the field of electricity, flat ground braids play a crucial role in the efficient transmission of electric current. They also play a role in equipment grounding. Unlike traditional cablesflat braids offer a wider contact surface. This makes them ideal for applications requiring high conductivity and flexibility.

Structure and composition of flat mass braids

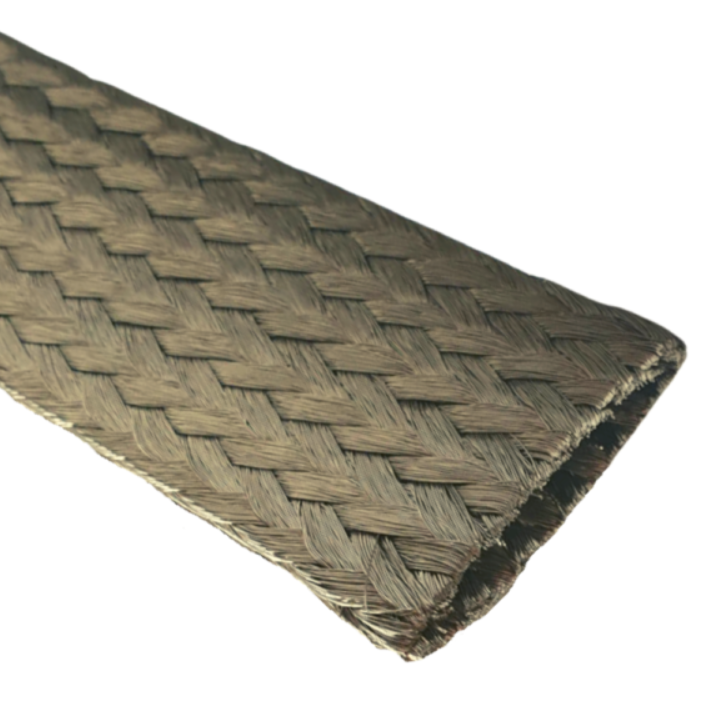

The flat braids are made up of strands of different materials (tinned copper, stainless steel or aluminum). The material is chosen according to the constraints or application required. The strands are braided together to form a flat, flexible band. This design ensures high conductivity while retaining great flexibility. This makes them easy to handle and install in a variety of environments.

Advantages of flat braids

High conductivity of ground braids

Thanks to their large contact surface flat braids offer superior electrical conductivity to round cables of the same cross-section. This makes them ideal for carrying high currents.

Flexibility of flat braids

The flat braids are extremely flexible. This makes them effective for applications requiring frequent movement or bending, such as in mechanical systems.

Flat braids: Easy to install

Because of their flexibility, flat braids are easy to handle and install in tight spaces or complex configurations. This reduces installation time and costs.

Flat braid applications

The flat braids are used in a wide range of electrical and electronic applications.

Flat braid grounding

The flat braids are used to establish ground connections in electrical installations and industrial equipment.

Earthing involves connecting a conductor or electrical equipment to earth, via a metallic connection. These connections are our grounding braids are designed to provide a safe path for leakage or short-circuit currents to earth. This ensures personal safety and protects equipment against overvoltage and electric shock.

Grounding

The grounding braids are used to connect electrical components such as transformers, circuit breakers, inverters and electric motors. This ensures safe and efficient power transmission.

Electromagnetic shielding of flat braid

The flat braids are also used as shielding elements in cables and electronic devices. For example, to protect against electromagnetic interference and reduce disturbance.

Standards and regulations for flat braids and mass braids

It is important to note that flat braids must be manufactured and installed in accordance with current electrical standards and regulations. Organizations such as the International Electrotechnical Commission (IEC) establish specific guidelines for the manufacture, testing and installation of flat braids. This guarantees their reliability and safety.

Flat braids: An essential role

The flat braids play an essential role in electrical applications, offering a unique combination of high conductivity, flexibility and mechanical strength. Their use in grounding, grounding and electromagnetic shielding helps to ensure the safe operation of electrical systems in a variety of environments. By complying with standards and good manufacturing and installation practices, the flat braids can provide a reliable and effective solution for a multitude of electrical and electronic applications.