The mass braidingalso known as grounding braid or shunt, is an essential element in many electrical and electronic systems. The ground straps ensure a secure connection to earth, which is crucial for the safety and proper operation of equipment. Here we explore how to size a grounding braid to meet the specific needs of your application:

-

- Choosing the right material (for flat ground braid, flat braid, braided sheath...)

-

- Select the appropriate section

Three criteria for choosing the right mass braid

Sizing a mass braiding depends on several factors. Firstly, the expected leakage current, the frequency of the current, the environment in which it will be used and the applicable standards.

Here are a few steps to help you choose the right mass braiding.

Leakage current calculation

Estimate the maximum leakage current the braid will have to carry. This figure will depend on system design and safety specifications. If you don't know your leakage current, you can simply check the amperage or electrical cross-section of your installation to choose the electrical cross-section of your grounding braid.

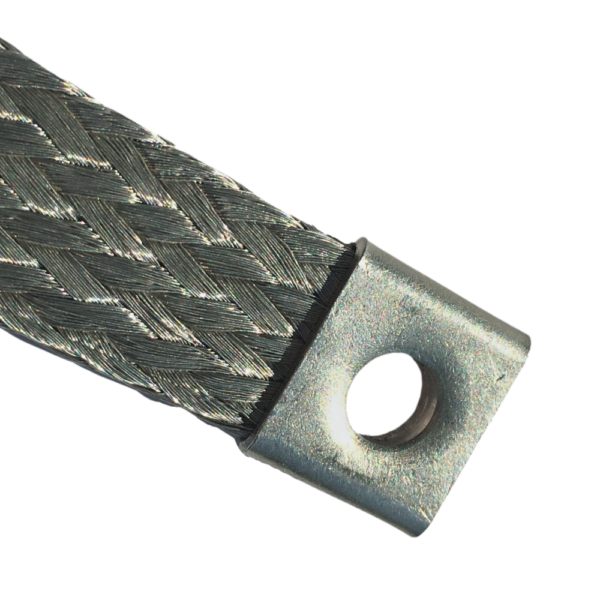

Choice of material

Select a suitable material according to the required electrical conductivity, corrosion resistance and flexibility. Commonly used materials are tinned copper, aluminum and stainless steel (inox) ground braids. Further down in this article, you'll find some recommendations on the specifics of each material.

Choosing the length of the ground strap

The length of the braid must be sufficient to reach earth or another gear directly, without unnecessary loops which could increase electrical resistance.

What material should you choose for your mass braid?

The choice of ground braid depends on the specific requirements of the application.

Here are some important considerations.

Choose tin-plated copper grounding braid

Tin-plated copper is widely used for its high electrical conductivity and corrosion resistance. Tin-plated copper is often preferred for improved resistance to oxidation.

Why choose aluminum mass braiding

Aluminum is a less expensive alternative to copper. It is lighter but less conductive, which means that a larger electrical cross-section may be required to achieve equivalent performance.

Why choose stainless steel mass braiding?

Stainless steel is chosen for its resistance to corrosion in particularly aggressive environments. However, it has a lower electrical conductivity than copper and aluminum.

How do you choose the right electrical cross-section for your grounding braid?

The electrical cross-section of the grounding braid is determined by the maximum current it must carry without excessive overheating.

Here are some general guidelines for selecting an electrical section.

Choose the electrical cross-section of your grounding braid according to the electrical cross-section or current of your installation.

To choose the right section for your grounding braid you simply need to know the current or electrical cross-section of your installation.

-

- For low leakage currents and low-power applications, a small braid cross-section may be sufficient. For example, braids from 2 to 20 mm².

-

- For high-power systems or industrial environments, a larger braid cross-section is required. For example, braids from 50 to 200 mm².

What do electrical standards say about choosing the electrical cross-section of your grounding braid?

Electrical standards stipulate that the braid or earth conductor must have at least the same cross-sectional area as the installation.

For example, if your installation has an electrical cross-section of 25, you will need a grounding braid with a minimum cross-section of 25 mm².

Select the right electrical cross-section for the chosen material

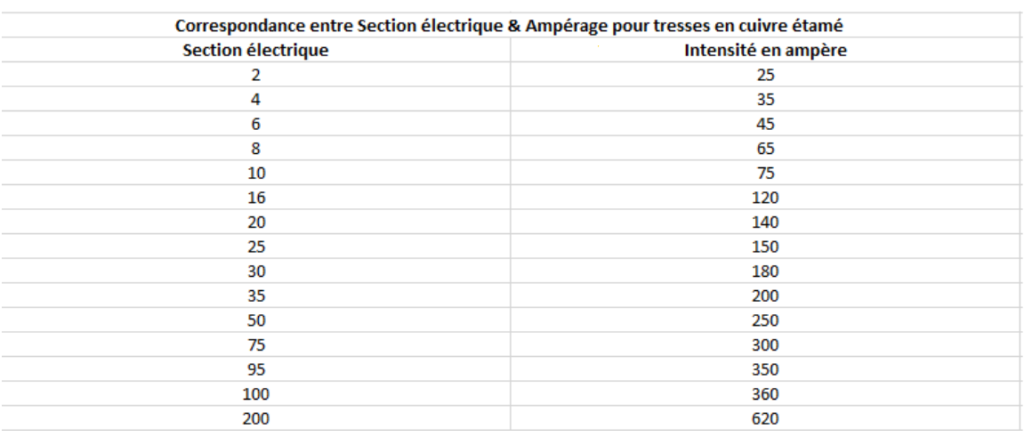

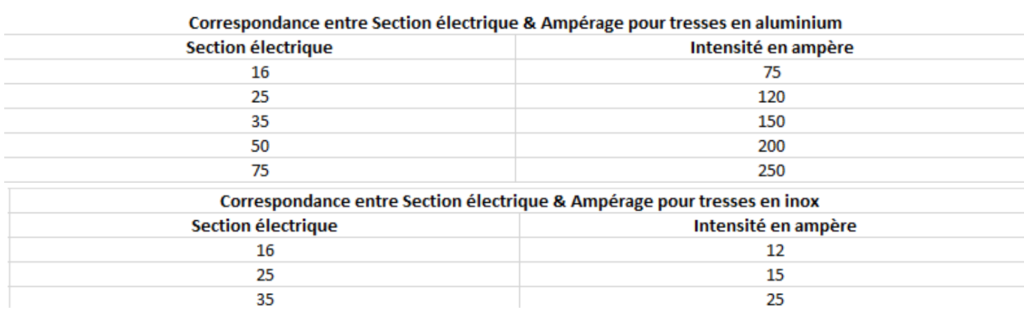

Depending on the material of your braid (tinned copper, aluminum or stainless steel), the correspondence between electrical cross-section and current will be different.

Here are the tables to help you choose your section according to the intensity and material of your desired braid .

In conclusion, dimensioning and selecting the grounding braid is essential to ensure the safety and reliability of electrical and electronic systems.

By taking into account leakage current, material and electrical cross-section, you can guarantee an effective ground connection and protection against electrical hazards.

It is always advisable to consult electrical engineering experts for critical or complex applications. Applicable standards and regulations should be consulted to ensure compliance with safety requirements.

If you're still hesitating, contact our teams for advice by clicking here !