Metal braided sleeving: robust protection for cables and wires

Metal braided sleeving is an essential component in many industrial

applications, providing reliable protection and secure management of cables and wires. The

braided design of braided cable sleeving gives them unique flexibility and strength, making them ideal for use in demanding environments. Two of the most commonly used materials for these braided sleeves are stainless steel and tinned copper. Let's explore the specific advantages of each type of braided sleeving. Click here to discover our products: https: //gaine-tressee.com/gaines-tressees-de-protection/gaines-tressees-metalliques/gaines-tressees-cuivre-etame/

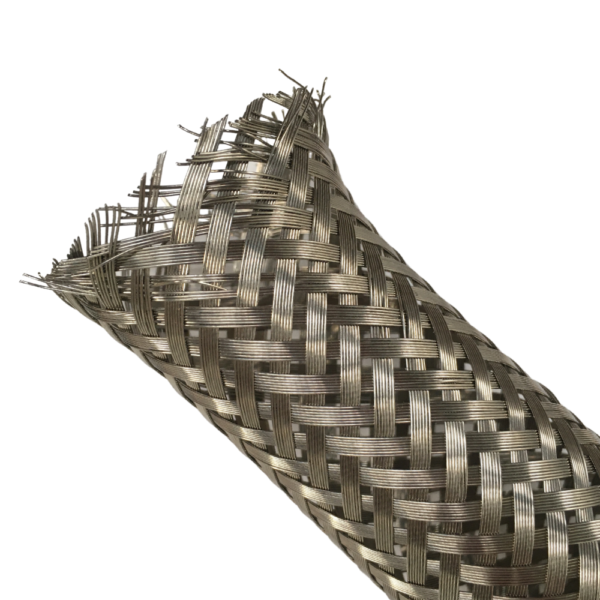

Stainless steel braided cable sheath: Durability and resistance to any challenge

Stainless steel braided sleeving, commonly known as stainless steel sleeving, is renowned for its exceptional durability and corrosion resistance. Stainless steel braided slee ving can withstand a wide range of environmental conditions, and is particularly well suited to corrosive environments and high-temperature applications. Stainless steel braided sleeving offers reliable protection against mechanical shocks, aggressive chemicals and corrosive elements, ensuring long life for the cables and wires it encases.

Tinned braided copper sheaths: Electrical conductivity and reliability

Tinned copper braid sleeving is widely used in electrical applications, thanks to its excellent electrical conductivity and resistance to oxidation. Copper braided sleeving provides effective protection for cables and wires, while maintaining optimum electrical conductivity.Tinned copper braids are particularly appreciated in installations where heat dissipation and protection against electromagnetic interference are essential. Their braided construction guarantees superior flexibility and robustness, making them easy to install and use in a variety of industrial and commercial applications.

How to choose the right braided sheath?

Metal braided sleeves in stainless steel and tinned copper offer robust, reliable protection

for cables and wires in a diverse range of applications. While stainless steel sheaths are

ideal for corrosive environments and high-temperature applications, braided sheaths in

tinned copper are preferred for their excellent electrical conductivity properties. Whatever

material you choose, these metal braided sleeves guarantee optimum performance and

extended cable and wire life, contributing to the reliability and efficiency of

electrical and electronic systems.